Javascript message

This site uses javascript. If javascript is disabled in your browser, some functionality may be impaired.

High-Performance Liquid Chromatography (HPLC) is a powerful tool for large-scale purification, and it stands out when compared to other purification methods. The advantages of using HPLC with Kromasil® chromatography media for industrial-scale operations are numerous and compelling, making it a go-to method for many industries, especially pharmaceutical industry requiring high levels of purity.

Efficiency

One of the primary benefits of HPLC in large-scale purification is its high throughput and efficiency. Modern HPLC systems are designed to handle significant volumes of material, ensuring that large quantities can be processed quickly and efficiently. This high throughput is essential for meeting the demands of industrial-scale production without compromising on the quality of the separation.

Scalability

Smooth scalability is another critical advantage of prep HPLC. Processes developed on a smaller scale can be effectively scaled up to industrial levels with minimal adjustments. This scalability ensures that the purification methods are robust and can be implemented consistently across different scales, from pilot to full production. By offering the same particle properties and chemistry over the full range of particle sizes, it is also possible to develop and scale-up seamlessly on different particle sizes of Kromasil® media.

Reproducibility

Consistency and reproducibility are crucial for large-scale operations, and HPLC excels in these areas. The method provides consistent and reproducible results, which is vital for maintaining product quality and meeting regulatory standards. Batch-to-batch consistency is particularly important in industries such as pharmaceuticals, where any variation can have significant implications. Kromasil® stationary phases have a remarkable record of batch-to-batch consistency over the years.

HPLC is renowned for achieving high purity levels, which is a critical requirement for many industrial applications. Whether in pharmaceuticals, biotechnology, or other sectors, achieving high purity is essential to meet stringent regulatory standards and ensure the safety and efficacy of the final product. This is highly important for medications that are taken over long period of time, if not a lifetime, like Insulin. HPLC’s ability to deliver such high purity makes it indispensable in these contexts.

Versatility, integration and sustainability aspects

The versatility of HPLC is another reason it is favored for large-scale purification. It can handle a wide range of compounds, including complex mixtures of small molecules, peptides, proteins, and other biologics. This versatility means that HPLC can be applied across diverse industrial applications, making it a flexible and valuable tool.

Integration with downstream processes is another significant advantage of using HPLC. The method can be seamlessly integrated with processes such as drying, crystallization, or formulation, creating an efficient and streamlined production workflow. This integration enhances overall efficiency and reduces the time required to bring products to market.

Compared to some other large-scale purification methods, HPLC can be optimized to use minimal solvents, minimizing environmental impact. With a reputed very high surface area, Kromasil® silica particles offers a potential of high loadability that also have a direct impact on reducing operational costs. The use of advanced solvent recovery systems further enhances this efficiency, in combination with durable Kromasil® media making HPLC a more sustainable choice.

Process control, data analytics and regulatory compliance

Automation and process control are integral features of large-scale HPLC systems. These systems are highly automated, reducing the need for human intervention and minimizing the risk of contamination. Advanced process control features allow for precise control over purification parameters, ensuring optimal performance and high-quality output.

Regulatory compliance is a critical consideration in many industries, and HPLC systems can be designed to comply with Good Manufacturing Practices (GMP) and other regulatory standards. This compliance is essential for the production of pharmaceuticals and other high-value products, ensuring that the purification process meets all necessary regulatory requirements.

Finally, large-scale HPLC systems come equipped with sophisticated monitoring and data analytics capabilities. These advanced monitoring and data analytics tools enable real-time monitoring of the purification process, ensuring quality control and facilitating process optimization. This capability is crucial for maintaining high standards and continuously improving the purification process.

In short, HPLC offers a range of significant advantages for large-scale purification, including high throughput and efficiency, scalability, consistency, automation, high purity, versatility, integration with downstream processes, minimal solvent usage, regulatory compliance, and advanced monitoring capabilities. These benefits make HPLC with Kromasil® chromatography media an essential tool for industrial-scale purification, particularly in industries where high purity and efficiency are paramount.

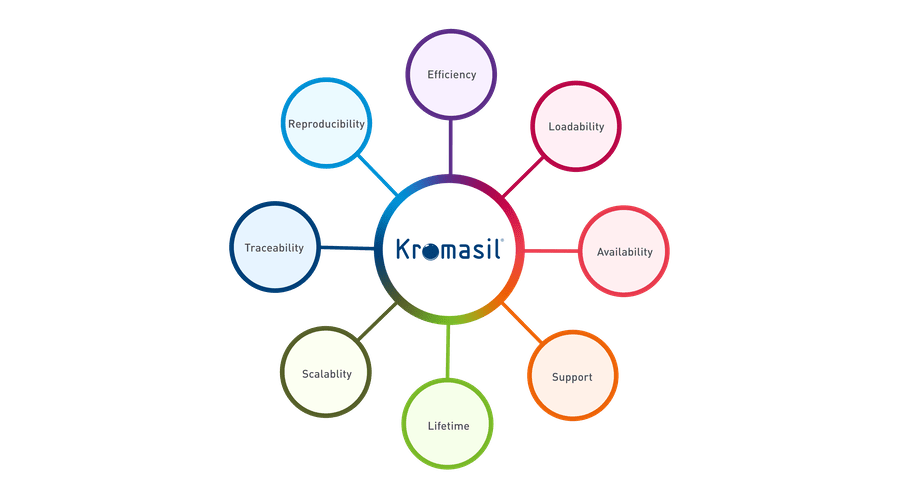

The Kromasil® values

2 min movie

2 min movie