Javascript message

This site uses javascript. If javascript is disabled in your browser, some functionality may be impaired.

A toolbox to reach your purification goals

GLP-1 agonists are a family of peptides that have become popular in the early treatment of diabetes type ll. Achieving the right purity for these peptides is however quite challenging.

A set of purification methods have been developed using Kromasil® stationary phases for removal of impurities in peptide crudes that can be combined in a systematic way to improve purity from crude to 99.5%. This set is called the GLP-1 agonist purification toolbox.

With a set of well adapted purification methods and routines in place, high efficiency and long column lifetime can be maintained to maximize throughput and productivity.

Liraglutide and Semaglutide

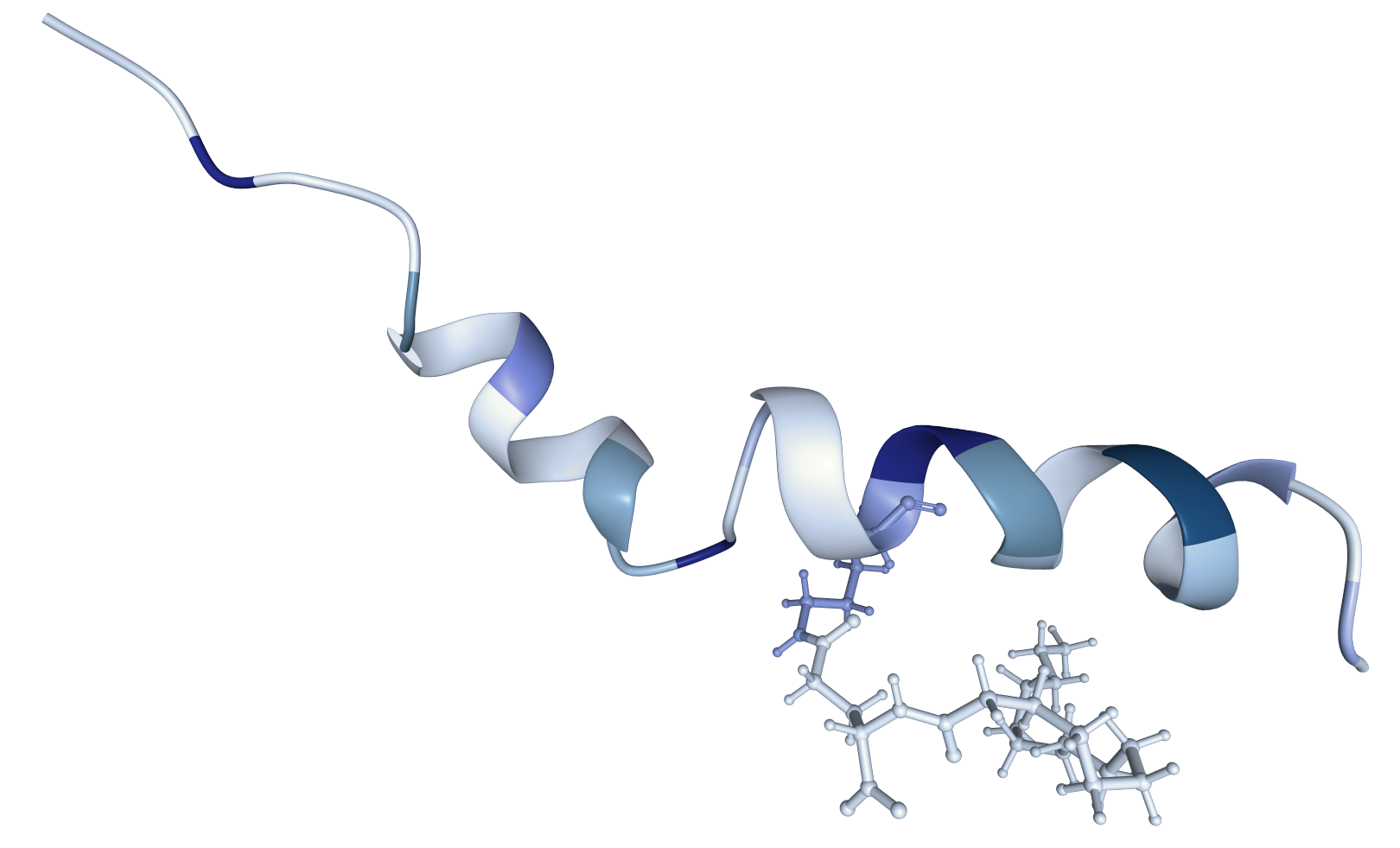

Liraglutide and Semaglutide are a couple of the main GLP-1 agonists commercially produced on the market. They have a couple of amino acid substitutions compared to human GLP-1 to slow down peptidase degradation and are both acetylated with a hydrocarbon side chain.

However, if inadequately handled during purification, they easily degrade or aggregate. Most of these issues are avoided when using the toolbox methods.

(pdb id 4apd) using Mol* Viewer (D. Sehnal et al (2021)

Nucleic Acids Research. doi: 10.1093/nar/gkab314) and RCSB PDB.

Reaching for 99.5% purity

Crudes of Liraglutide are typically anything in the range from 10 to 50% in purity when entering downstream processing. The goal of the toolbox is to offer purification methods that will bring purity up to 99.5%.

Tools selection

Operating the major factors affecting chromatography efficiency in HPLC, many different combinations of the following properties were screened:

- Kromasil® stationayy phase

- Mobile phase organic solvent

- Mobile phase buffer

The screening compilation resulted in set of methods combinations with focus on the relative location of the impurities removed from the crude: back or front. The most efficient combinations have been compiled in the tables below.

Toolbox methodology

The methodical approach is to select two methods from the toolbox (tables below) that will target front and back impurities from the crude, respectively. In some cases this can be achieved in a single step or on a single phase.

Examples with Semaglutide

Example 1

In this example, starting with a 30% purity crude of Semaglutide, the two-steps method uses Kromasil® C4 in both steps, but at different pH, obtaining 92.2% purity after the first step and then 99.5% after the second step.

Example 1 - Purification step 1

Example 1 - Purification step 2

Example 2

Example with Semaglutide using phosphate buffers at different pH on the same C4 packing media. Also starting with the 30% purity crude, the first steps at low pH reaches a 90.5% purity. The second step is run at neutral pH achieving the final 99.5% purity.

Example 2 - Purification step 1

Example 2 - Purification step 2

Example 3

Example using the dedicated Kromasil® diC4 phase for GLP-1 receptor agonists and Kromasil® Phenyl with 2 fairly neutral buffer steps with potassium phosphate and ammonium acetate, respectively.

Example 3 - Purification step 1

Example 3 - Purification step 2

Examples with liraglutide

Example 1

In this first example, starting with a 50% purity liraglutide crude, a first method using Kromasil® Phenyl targets front impurities, obtaining a 94% purity. To reach a final purity of above 99.5%, a second step on Kromasil® C4 is run, removing remaining back impurities.

Example 1 - Purification step 1

Example 1 - Purification step 2

Example 2

In this example, starting with a 50% purity crude, a first step using Kromasil® C8 targeting both front and back impurities, and reaching a 98% purity. To achieve the final purity of above 99.5%, the second step is run on Kromasil® C4, removing the remaining impurities.

Example 2 - Purification step 1

Example 2 - Purification step 2

Example 3

Starting with as low as a 15% purity Liraglutide crude, running both steps on Kromasil® diC4 at neutral and mild basic pH, stepping up purity to 97.1% and >99.5% respectively.

Example 3 - Purification step 1

Example 3 - Purification step 2

Example 4

Starting with a 20% purity Liraglutide crude, running both steps on Kromasil® diC4 at neutral and mild basic pH, stepping up purity to 96.4% and >99.9% respectively.

Example 4 - Purification step 1

Example 3 - Purification step 2

Doing it right

While peptide crudes can be challenging when repeatedly injected on an HPLC column, having a regeneration routine can be beneficial to maintain a good column lifetime and efficiency and thereby process productivity.

Troubleshooting back-pressure increase

When purifying demanding peptide crudes like Liraglutide, the column quickly gets fouled by absorbed impurities with repeated injections, even when performing a traditional 2 column volume wash between injections.

We propose here to perform an additional wash under mild conditions after a sequence of injections to quickly and fully recover column capacity and efficiency, optimizing productivity and throughput.

A Initial injection

B After 30 sequential prep injections

C After mild regeneration wash

Contact us

Are you also working on some GLP-1 agonist peptides and is interested in how this toolbox can reduce your development time and boost your productivity? Don’t hesitate to contact us and reach out to our team of skilled application scientists for more details: