Javascript message

This site uses javascript. If javascript is disabled in your browser, some functionality may be impaired.

Care & Use of Kromasil HPLC Columns

Please read this care and use information before using the column.

All Kromasil columns are individually manufactured and tested to meet strict specification

criteria. The following measures will enhance their performance and lifetime.

Column installation

System dead volume:

Reduce dead volume in the system to a minimum by using small internal diameter connection tubing, for analytical columns 0.010". Keep these tubing lengths between injector, column and detector as short as possible.

Column connection:

For optimum performance, it is important that the tubing used to connect the column to the injector or detector is swaged into position such that it abuts the internal shoulder of the fitting.

Equilibration:

The storage solvent in a new column is the mobile phase used to evaluate the column unless otherwise specified on the chromatogram. Initially care should be taken not to pass any material through the column that may precipitate in the storage solvent. Ensure that the column is fully equilibrated to the mobile phase prior to starting an analysis. A normal phase silica column usually requires more conditioning than a reverse phase column. The direction of flow is marked on the column.

Performance testing:

It is recommended that the performance of columns is tested on arrival and at periodic intervals during use. The performance parameters measured are defined above.

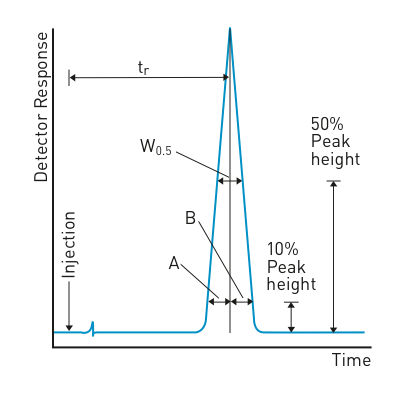

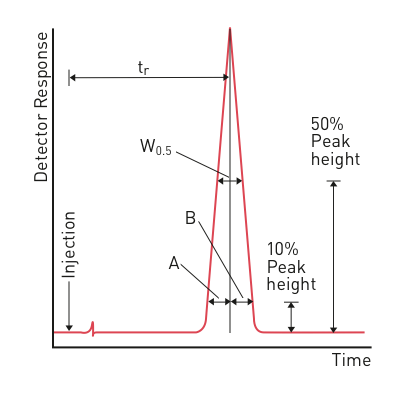

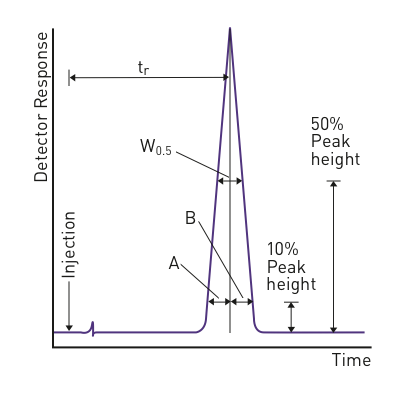

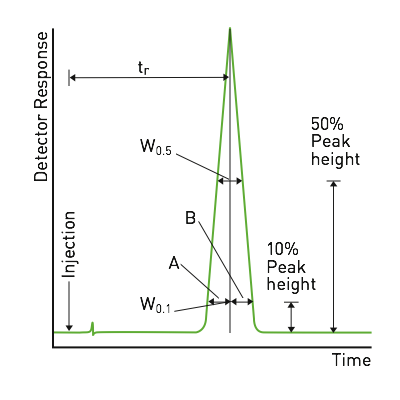

Efficiency: N = 5.54(tr/W0.5)2

Asymmetry factor: As0.1 = B/A

Safety

Maximum operating pressure = 400 bar ( ≈ 6000 psi)

Maximum temperature = 60°C

Operational guidelines

HPLC solvents:

Use only HPLC grade solvents and freshly prepared aqueous buffer solutions to minimize bacterial growth. A slip-on pump inlet filter will remove extraneous particles.

Mobile phase pH: The recommended mobile phase pH for Kromasil columns packed with CN, HILIC-D, C4, diC4, C8, C18 and Phenyl phases, is between 1.5 and 9.5. For NH2 phases, lifetime can be reduced when using with aqueous mobile phases; for longest lifetime only NP (normal phase) conditions are recommended.

It is suggested that new mobile phase solutions are used regularly. Do not top off mobile phase bottles. If large volumes of mobile phase are prepared at one time, the unused solution should be kept in the refrigerator to avoid bacterial growth and unnecessary evaporation. Always filter the mobile phase using a 0.2 μm filter. This will ensure maximum column life.

Pressure:

Exposure of a column to rapid changes in back pressure or to pressures greater than 400 bar/6000 psi may reduce column life.

Storage:

Wash out all water and buffers from bonded silica columns and store in organic solvent. Unbonded silica columns may be stored in hexane or similar organic solvent. Keep in a cool area and replace end-caps to prevent the packing bed drying out.

Mechanical damage:

Protect the column from mechanical shock. Dropping or banging a column can impair its performance.

Fittings – torque:

Excessive tightening of the column end fittings will result in damage to the column tubing or fittings. Removal of an end fitting to replace a frit or top-up the packing material should be regarded as a last resort to prolong column life.

Care & Use of Kromasil Eternity Columns

Please read this Care and use information before using the column.

All Kromasil Eternity and EternityXT columns are individually manufactured and tested to meet strict specification criteria. the following measures will enhance their performance and lifetime.

Column installation

System dead volume:

Reduce dead volume in the system to a minimum by using small internal diameter connection tubing, for analytical columns 0.010”. Keep the tubing lengths between injector, column and detector as short as possible.

Column connection:

For optimum performance, it is important that the tubing used to connect the column to the injector and the detector is swaged into position such that it abuts the internal shoulder of the fitting.

Equilibration:

The storage solvent in a new column is the mobile phase used to evaluate the column unless otherwise specified on the chromatogram. initial care should be taken not to pass any material through the column that may precipitate in the storage solvent. ensure that the column is fully equilibrated to the mobile phase prior to starting an analysis.

Guard cartridges:

In order to extend the column lifetime by avoiding inlet frit blockage and irreversible sample adsorption, the use of a guard cartridge is recommended. Guard cartridges are available for all Kromasil eternity HPLC columns.

Operational guidelines

HPLC solvents:

Use only HPlC grade solvents and freshly prepared aqueous buffer solutions to minimize bacterial growth. a slip-on pump inlet filter will remove particles.

Mobile phase pH:

The recommended mobile phase pH for a Kromasil eternity column is between pH 1 and 12. this will ensure maximum column lifetime.

Pressure:

Exposure to rapid changes in back pressure or to pressures greater than 400 bar (6 000 psi) for HPLC columns or 1000 bar (15 000 psi) for UHPlC columns may reduce column lifetime.

Storage:

Wash out all water and buffers from bonded silica columns and store in organic solvent. Keep in a cool area and replace end caps to prevent the column- from drying out.

Mechanical damage:

Protect the column from mechanical shock. dropping or banging a column can impair its performance.

Temperature:

Operating at temperatures above 60°C for an extensive period of time may reduce column lifetime.

Column warranty:

All columns are warranted to meet the specifications stated on the test Chromatogram supplied with the column. for additional information and limitations in this matter, log on to www.kromasil.com

Performance testing

It is recommended that the performance of a column is tested on arrival and at periodic intervals during use. the performance parameters measured are defined below.

Plates: N = 5.54·(tr/W0.5)2

Asymmetry factor: As0.1 = B/A

Care & Use of Kromasil Chiral HPLC Columns

Please read this information carefully before using the column.

All Kromasil Chiral columns are

individually manufactured and tested to meet strict specification criteria. The following measures

will maintain their performance and lifetime.

Products intended

Those instructions are applicable for the following Kromasil coated chiral phases:

for normal phase chromatography (NP):

- Kromasil AmyCoat

- Kromasil CelluCoat

for reversed phase chromatography (RP):

- Kromasil AmyCoat RP

- Kromasil CelluCoat RP

Important

The entire HPLC system, including solvent lines, injector, loops or

autosampler has to be purged with a solvent compatible with the Kromasil coated chiral column. A

thorough instrument purge with 2-propanol is recommended. Solvents commonly used for other normal

phase separations, such as e.g. TFA, dichloromethane,

DMSO, DMF,

ethyl acetate, acetone orchloroform could severely damage the Kromasil coated chiral column even at residual quantities.

Changing mode (from RP to NP or vice-versa) on a coated chiral phase column may permanently

impair its performance.

Column installation

Shipping solvent:

The normal and reversed phase columns are shipped in heptane /2propanol (90/10)¹ and acetonitrile/water (40/60)¹, respectively

System dead volume:

Reduce dead volume in the system to a minimum by using small internal diameter connection tubing, for analytical columns 0.010”. Keep the tubing length between injector, column and detector as short as possible.

Column connection:

The column should be mounted according to the flow direction indicated on the column. For optimum performance, it is important that the tubing used to connect the column to the injector or detector is swaged into position such that it abuts the internal shoulder of the fitting. Excessive tightening of the column end and fittings will result in damage to the column tubing and/or fitting.

Performance Testing:

It is recommended that the performance of columns is tested upon arrival and at periodic intervals during use. The test conditions are described on the test chromatogram, the calculations of plates and symmetry as described below.

Plates: N = 5.54·(tr/W0.5)2

Asymmetry factor: As0.1 = B/A

Mechanical damage:

Protect the column from mechanical chock. Dropping or banging a column can impair its performance.

Storage:

Wash out all additives from normal phase columns with a neutral mobile phase such as heptane/2propanol (90/10)¹ and buffer from reversed phase columns with a salt-free mobile phase such as acetonitrile/water (40/60)¹. Close the column openings with the end-caps in order to prevent the packing from drying out and keep the column at ambient temperature (15-25°C).

Operational guidelines

Flow rate and pressure limitation:

Maximum operating pressure: 400 bar (6000 psi)

Temperature limits:

Generally, Kromasil coated chiral columns can be operated between 0 and 40°C, except for buffered basic mobile phases. See compatibility table below for actual limits.

Compatible mobile phases

If you wish to use solvents, buffers or additives others than mentioned on this page, please consult the Kromasil technical support team first (kromasil@nouryon.com).

Changing mode (from RP to NP or vice-versa) on a coated chiral phase column may

permanently impair its performance.

Switching between acetonitrile and methanol in the mobile phase on coated chiral phases

may irreversibly damage the coating. When switching between mobile phases containing these

solvents, run an intermediate wash with 100% ethanol for Kromasil AmyCoat / AmyCoat RP or

2-propanol for Kromasil CelluCoat / CelluCoat RP.

Compatible normal phase mobile phases:

Possible combinations and compositions for Kromasil AmyCoat and Kromasil CelluCoat are described in the tables below:

| alkane/2-propanol | 100/0 to 0/100 |

| alkane/ethanol | 100/0 to 0/100 |

| alkane/methanol² | 100/0 to 0/100 |

| alkane/MTBE | 100/0 to 50/50 |

| ethanol/methanol | 100/0 to 0/100 |

| (SFC) CO2/alcohol | 100/0 to 50/50 |

| acetonitrile/methanol | 0/100 to 15/85

85/15 to 100/0 |

| acetonitrile/2-propanol | 100/0 to 0/100 |

| ethanol/MTBE | 100/0 to 70/30 |

| acetonitrile/methanol | 85/15 to 100/0 |

| ethanol/MTBE | 100/0 to 50/50 |

Mobile phase additives for normal phase:

For basic samples we recommend the addition of 0.1% (< 0.5%) DEA and for acidic samples the addition of 0.1% (< 0.5%) TFA.

Switching between mobile phases on normal phase columns.

When switching between non-miscible solvents, use 100% 2-propanol as a transition mobile phase. Kromasil AmyCoat will also need a subsequent wash with 100% ethanol.

When switching from 100% polar mode to alkane/alcohol run a transition wash with 100% ethanol for Kromasil AmyCoat or 2-propanol for Kromasil CelluCoat.

Otherwise, no intermediate column wash is necessary. An adequate equilibration time is depending on the column dimension. By increasing the flow rate the equilibration time can be reduced. However, stable base line should always be reached before a separation is started.

Compatible reversed phase mobile phases:

Possible combinations and compositions for Kromasil AmyCoat RP and Kromasil CelluCoat RP are described in the table below.

To avoid salt precipitation, a wash with acetonitrile/water (40/60)¹ is recommended when switching from buffer to 100% organic modifier.

| Aqueous solution | Organic modifiers | Organic part | Temperature |

|---|---|---|---|

| water | acetonitrile³,

methanol³, ethanol, 2-propanol |

10-100 % | 5-40°C |

| potassium phosphate buffer

0-0.5 M, pH 2.0-8.0 Suggestions: 50 mM at pH 2.0 20 mM at pH 8.0 |

10-85% | pH < 7: 5-40°C

pH > 7: 5-25°C |

|

| phosphoric acid, aqueous solution at pH 2.0 | |||

| sodium hexafluorophosphate aqueous solution

Suggestions: 100 mM at pH 2.0 50 mM at pH 5.0 |

|||

| sodium borate buffer

0-0.2 M, pH 7.5-9.0 Suggestion: 20 mM at pH 9.0 |

5-25°C | ||

| acetic acid, 0.1%¹ | 5-40°C |

¹: volume by volume.

²: due to limited miscibility of methanol in alkanes, ethanol should be added as a mediator when exceeding 5% methanol.

³: Read the red-boxed note about these solvents

Care & Use of Kromasil SFC Columns

Please read this information carefully before using the column.

All Kromasil SFC columns are individually manufactured and tested to meet strict specification criteria.

The following measures will maintain their performance and lifetime.

All Kromasil columns are individually manufactured and tested to meet strict specification criteria. The following measures will enhance their performance and lifetime.

Column installation

System dead volume:

Reduce dead volume in the system to a minimum by using small internal diameter connection tubing, for analytical columns 0.25 mm (0.010”) or less. Keep the tubing lengths between injector, column and detector as short as possible.

Column connection:

For optimum performance, it is important that the tubing used to connect the column to the injector or detector is swaged into position such that it abuts the internal shoulder of the fitting.

Equilibration:

The storage solvent in a new column is the mobile phase used to evaluate the column unless otherwise specified on the chromatogram. Initially, care should be taken not to pass any material through the column that may precipitate in the storage solvent. Ensure that the column is fully equilibrated to the mobile phase prior to starting an analysis. A normal phase silica column usually requires more conditioning than a reverse phase column.

Operational guidelines

Solvents:

Use only HPLC/UHPLC grade solvents and freshly prepared buffer solutions to minimize bacterial growth. A slip-on pump inlet filter will remove extraneous particles. It is suggested that an inline filter is used just before the inlet of the column to minimize entry of particles to the column and extend the column’s lifetime.

Mobile phase pH:

The recommended mobile phase pH for Kromasil columns packed with bonded silica phases, is between 1.5 and 9.5. It is suggested that new mobile phase solutions are used regularly. Do not top off mobile phase bottles. If large volumes of mobile phase are prepared at one time, the unused solution should be kept in the refrigerator to avoid bacterial growth and unnecessary evaporation. Always filter the mobile phase using a 0.2 μm filter. This will ensure maximum column life.

Sample:

Always use fresh sample and filter it through a 0.2 μm filter.

Pressure and Temperature:

Exposure of a column to rapid changes in back pressure may reduce column life. It is suggested that the column is operated below 75% of the maximum system pressure. The column should be run below 60 °C.

Storage:

Wash out all water and buffers from bonded silica columns and store in organic solvent. Unbonded silica columns may be stored in hexane, heptane or similar organic solvent. Keep in a cool area and replace end-caps to prevent the packing bed drying out.

Mechanical damage:

Protect the column from mechanical shock. Dropping or banging a column can impair its performance.

Fittings – torque:

Excessive tightening of the column end fittings will result in damage to the column tubing or fittings. Removal of an end fitting to replace a frit or top-up the packing material should be regarded as a last resort to prolong column life.

Performance testing:

It is recommended that the performance of columns is tested on arrival and at periodic intervals during use. The performance parameters measured are defined above.

Efficiency: N = 5.54(tr/W0.5)2

Asymmetry factor: As0.1 = B/A

Lost your column documentation?

A copy of the test chromatogram included in the Kromasil column box can be requested from here.