Javascript message

This site uses javascript. If javascript is disabled in your browser, some functionality may be impaired.

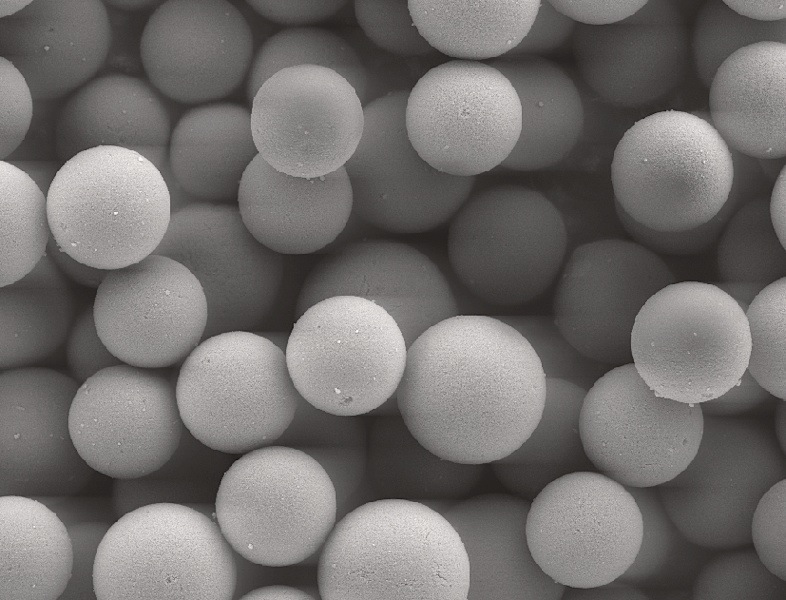

The perfectly shaped silica

The Kromasil® Classic platform is based on perfectly spherical silica-based materials to improve efficiency and decrease costs in laboratory analysis and purification steps.

Separates most substances

Kromasil® media’s combination of high pore volume and surface area, together with excellent mechanical and chemical stability, is unmatched for the separation of a wide variety of substances from small molecules to peptides and proteins. The pore structure is ideal for high loadability and long-term durability, making a difference in packing and performance that users have come to appreciate over time. This acceptance is valid across the wide spectrum of the Kromasil® offering, from small particles packed in analytical 2.1 mm columns to larger particles packed in wide diameter columns for purifications using dynamic axial compression (DAC) equipment.

Surface properties

The Kromasil® silica surface is topographically smooth and completely free from micro cavities. The surface silanol groups are evenly distributed and relatively neutral in their nature. These factors, combined with the high reproducibility of the Kromasil® silica surface, are the foundation for a reproducible bonding process and derivatized product.

Metal impurities

Strongly bound metal ions present in the silica bulk and in the surface layers are in most cases an outcome of the silica manufacturing process. These metal ion species should be distinguished from adsorbed metal ion species, introduced in the final product due to use of metal ion containing solvents, chemicals etc.

It is often possible to remove adsorbed metal ion species during a regeneration process in contrast to the “built-in”, strongly bound, metal ions, which are part of the final product. It is well known that strongly electronegative metal ions (e.g. bivalent iron and trivalent aluminum) in the silica matrix have the ability to enhance the acidity of silanols in their close proximity.

Increased acidity of silanols provides a higher possibility for ion-exchange interactions at any given pH. Moreover, metal ions present in the silica surface layer are able to interact directly with analytes that have Lewis-base properties.

The effect of metal ions in the silica matrix and in the silica surface layer.

The direct metal-analyte interaction is most pronounced for chelating substances, but it also affects the chromatographic behavior of acids, alcohols, and amines.

| Metal | Batch no | |||

|---|---|---|---|---|

| 15705 | 15046 | 17365 | 17892 | |

| Na | 2.8 | 4.2 | 6.3 | 6.1 |

| Al | <1 | <1 | <1 | <1 |

| Fe | 1.1 | <1 | 1.2 | <1 |

Derivatization of Kromasil® silica

Even if many stationary phases are launched every year, the C18 phase is still the most popular phase on the analytical market. Extensive quality controls on every raw material together with several in process controls (IPC) throughout the Kromasil® manufacturing process ensure a reproducible final quality of the derivatized phases of Nouryon.

Surface coverage

To ensure high chemical stability and excellent chromatographic performance, Kromasil® stationary media is produced with an optimized bonding step for surface coverage. Kromasil® RP products are manufactured by using monofunctional silanes. This together with the Kromasil® silica gives outstanding batch-to-batch reproducibility and high chemical stability.

Hydrophobicity

The hydrophobicity of an RP-phase is related to the silica matrix, the silane used for modification, the surface coverage, and the surface distribution of functionalities. Generally, Kromasil® RP-phases are considered to have high surface hydrophobicity.

This high hydrophobicity has two major advantages:

- High surface hydrophobicity provides good separating power. The retention of analytes can then be adjusted by the mobile phase conditions, upon need.

- High surface hydrophobicity provides good long-lasting performance, i.e. high chemical stability.

Endcapping

Endcapping is used to minimize undesired interactions between residual silanols and analytes. In the manufacturing process of Kromasil, a proprietary highly efficient technique is used to reduce these silanols.

Symmetrical peaks when using Kromasil

It is well known that residual silanol groups lead to severe peak tailing due to undesired interactions between the analyte and the stationary phase. Kromasil® RP-phases show excellent peak shape for both acidic and basic compounds.

Separation of butyl benzoic acid and toluene.

Separation of propranolol, diphenhydramine, acenaphthene and amitriptyline.

Chemical stability

Kromasil® chromatography media are well known for their high performance in both analytical and preparative chromatography. Mechanical and chemical stability are the cornerstones of Kromasil, as stability determines the lifetime of columns in analysis as well as the stationary phase in purification. In general, at a low pH, bonded phases can be hydrolyzed, resulting in a less hydrophobic surface. At a higher pH, the silica matrix itself can be dissolved, which means loss of both of both the silica and bonded phase.

Working with silica-based materials outside their optimum pH conditions can result in changed retention times and poor peak shape. However, for Kromasil® medias it has been shown that the product responds well to long-term exposure to pH 2 and pH 10.

Availability range

Kromasil® Classic products are available in particle sizes from 1.8 to 16 µm (larger particles can also be produced) with a narrow particle size distribution for high efficiency, low pressure drop, and best total economy in chromatographic analyses and purifications. The surface chemistries include bare silica (SIL) and various derivatizations like alkyl chains (C4, C8 and C18), phenyl, amino (NH2), diol, and cyano (CN). Within the Kromasil® Classic platform, Nouryon offers three families of products based on pore sizes: 60, 100 and 300 Å.

The stationary phases are available as slurry-packed columns, from 2.1 mm ID up to 50 mm ID, and as bulk, from gram quantities up to several metric tons.

With the Kromasil® Classic range of products, users can run normal phase (NP), reversed phase (RP), hydrophilic interaction liquid chromatography (HILIC), as well as supercritical fluid chromatography (SFC) separations and purifications.

| Stages | ||||

|---|---|---|---|---|

| Discovery | Method validation, QC | Purification | Production | |

| Product format | columns | columns | columns/bulk media | bulk media |

| Scale | UHPLC/ HPLC |

UHPLC/ HPLC |

semipreparative HPLC |

preparative HPLC |

| Column i.d. [mm] | 2.1 - 4.6 | 2.1 - 4.6 | 10 - 50 | ≥ 50 |

| Particle size [µm] | 1.8 - 5 | 1.8 - 5 | 5 - 10 | ≥ 10 |